Welcome to Yangzhou Guoxing Technology Co., Ltd [official website]

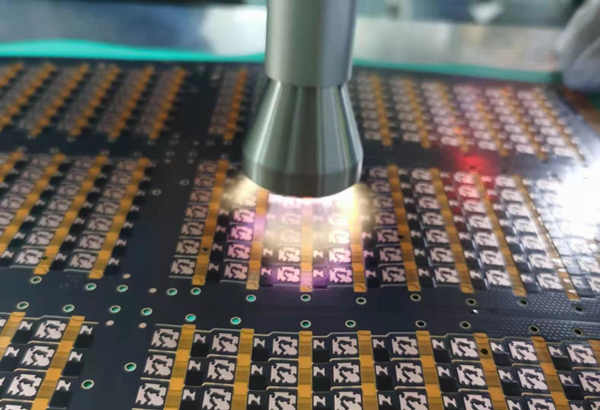

Plasma surface treatment machine principle, advantages, service-Guoxing technology, technology to rejuvenate the country, let’s take a look at the cleaning process principle of plasma cleaning: The cleaning process of plasma cleaning is divided into two processes from the principle. Process 1 is: the removal of organic matter. Firstly, gas molecules are activated by the principle of plasma, and then O, O3 is used to react with organic matter to achieve the purpose of eliminating organic matter; For: surface activation, firstly use the principle of plasma to activate gas molecules, and then use the surface activation of O, O3 oxygen-containing functional groups to improve the adhesion and wetting properties of the material. The plasma cleaning machine provided by Yangzhou Guoxing Technology Co., Ltd. has good effects on coating and plating the surface of various materials, enhancing adhesion and bonding strength, and removing organic contaminants on the surface of the materials at the same time. Plasma can not only activate the surface to facilitate the immobilization of biomolecules, but also produce a smooth surface to resist biological contamination, or be used for metered drug formulation. Plasma can also improve the performance of microfluidic devices. The microchannel on the diagnostic device can become more "infiltrating" to biological fluids without affecting its own analysis performance. Plasma is also used in some low-end technical fields, such as improving the ink marking of the catheter and improving the adhesion of the needle to the barrel. The plasma cleaning machine of Yangzhou Guoxing Technology has high stability, good effect, long-term work involved, and can be used for batch continuous production.

Next, let’s take a look at the cleaning advantages of plasma surface treatment machine equipment: the object after cleaning is dry, then it does not need to be dried, and can proceed to the next process. We can also design our plasma equipment process as an on-line cleaning method, which not only saves costs, but also saves time and effort, and improves production efficiency. The second advantage of plasma equipment cleaning is that it has no pollution, no harmful substances, and avoids many problems that are more likely to occur like wet cleaning. Plasma surface treatment machine cleaning can improve the cleaning efficiency, achieve surface modification, and improve product performance and yield. Generally speaking, general workpieces can be cleaned in a few minutes without any cumbersome process , As long as you can operate the plasma equipment. Yangzhou Guoxing technology products are mainly used in the manufacturing fields of semiconductors (chips and packaging), panels and camera modules, electronic circuit boards, automobiles, medical and cosmetics. Customers include Luxshare Precision, OFILM, Huahong Grace, Samsung Electronics, First-class electronics manufacturing companies such as Taiwan Xinxing Group. The founding team of the company is composed of veterans and a team of PhDs, and has been deeply involved in the field of equipment and electronics manufacturing for nearly two decades. Our innovative project "Continuous Plasma Etching Line and Nano Carbon Film Processing System" won the special prize of the first "Jiangdu Cup" China Innovation and Entrepreneurship Competition in 2019, and won the government's 10 million equity investment.

Yangzhou Guoxing Technology Receives Commendation Guoxing Technology also provides external processing services: A: After drilling the flexible board, rigid-flex board, high-thickness-to-diameter ratio rigid board, the hole wall is etched before the copper sink, and the hole wall is free of slag; B: PTFE (Teflon) and other high-frequency microwave boards The surface of the hole wall before copper sinking is activated; the board surface is activated before the solder mask; C: HDI board removes carbide after laser drilling; D: The surface of the rigid-flex board is roughened before pressing, and the bonding force can be increased by more than ten times without delamination; E: The surface treatment before the reinforcement of the flexible board, the cover film, and the steel sheet reinforcement, so that the reinforcement does not fall off and enhances the bonding force; F: The surface of the pad is cleaned and activated before wire bonding, which can improve the bonding force; G: The soft plate is gold-plated, and the surface of the pad before the gold is clean, which can replace the traditional plate grinding machine; H: Improve the solderability of SMT, improve the poor tin on tiny pads, improve the poor tin on BGA, false soldering, etc.; I: Epistar, LED bonding, cleaning.

Consult now